Production

and use

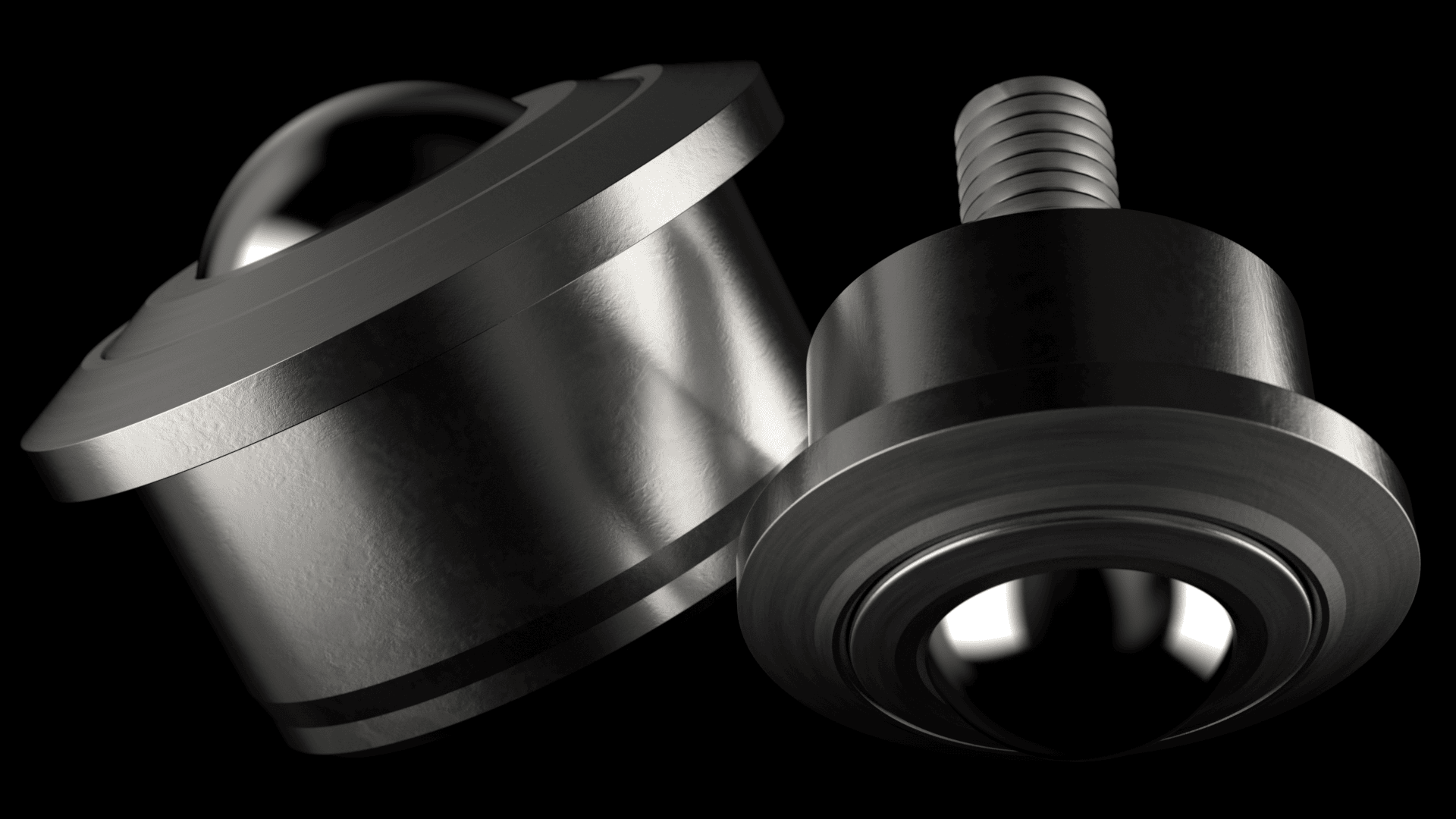

RGPBALLS. Ball transfer units are multidirectional systems for the linear handling of loads.

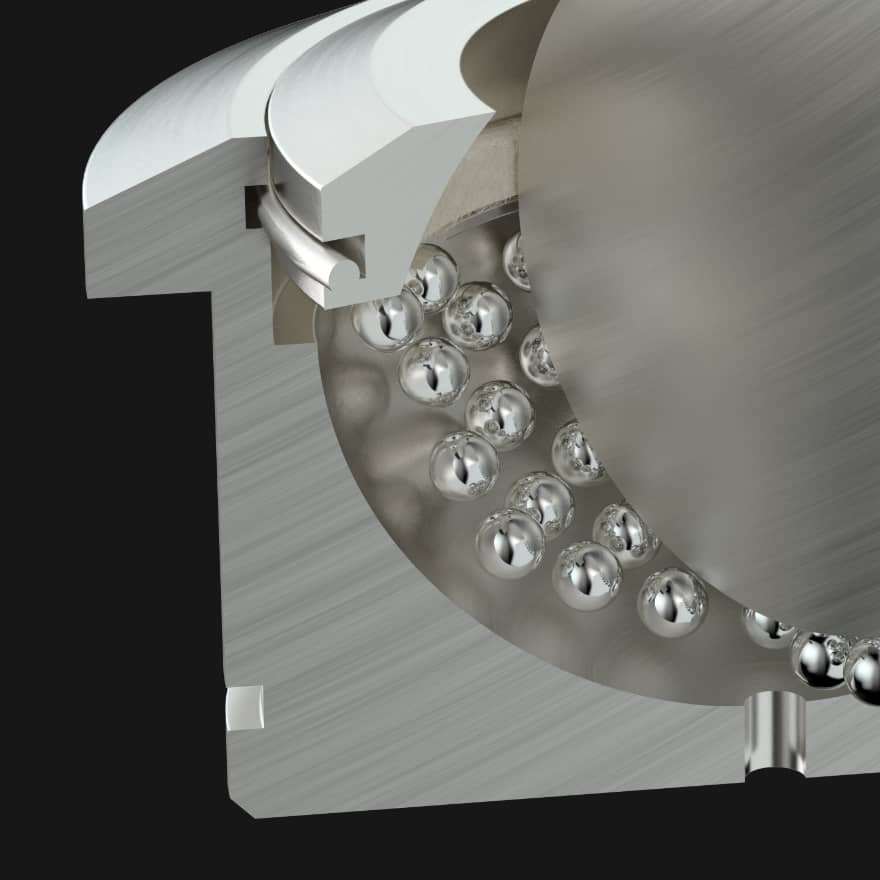

They consist of a large ball that rolls on a defined quantity of small diameter balls, all enclosed in a hemispherical seat.

INTERNAL STRUCTURE

100% MADE IN ITALY

We oversee the design and manufacture of our ball bearings in our laboratories.

Thanks to the care with which the various components are processed, friction is particularly low, Thus allowing the strength required to move the Loads to be significantly reduced.

Housings in different materials and types

Bar-turned and hardened steel housing

They are normally used to handle Heavy loads, strong stresses, impacts and severe Conditions in general. For high flow rates, Similar versions are available specifically

Pressed metal sheet components

They are instead preferable in applications which involve Lower loads. They combine good smoothness at adequate flow rates, allowing a cheaper final Price.

With plastic material components

Suitable for the chemical, pharmaceutical and food industries as they comply with EC 10/2011, NSF/ANSI 51 food certifications. They also provide excellent dielectric and insulating properties and are not gas permeable.

Dimensions and materials

Balls of customisable size and materials.

The production range starts with a main ball of 12 mm diameter up to a maximum of 90 mm, which can be made of different types of materials such as steel, stainless steel, pressed metal sheet and Plastic materials.

Among the versions made, different types of coatings are also available, which are useful to preserve oxidation resistance over time. Even the balls used can be chosen from different types of materials according to the final application. All components can be assembled in different materials, to meet any specific final use.

The temperature of use

The temperature of use is normally included between -20 ° C to +100 ° C (+70 ° C continuously and +100° C intermittent). These values do not affect the correct functioning of the units.

They can even reach temperatures up to +150/200 ° C by eliminating the internal dust seal. For a high temperature use we usually suggest our version with all components made of AISI 420 stainless steel, without felt seal.

It should be considered that the higher the temperature of use, the lower the load factors.

Ball bearings in versions with plastic balls or completely made of plastic are suitable for use at room temperature.

The little thing that gets the world moving.

Our balls are used in the most varied industrial sectors, from small objects to large plants.

Whether you are a small company or a multinational one, we are by your side to make your job easier and your applications more performing.

- Airport loading and unloading equipment

- Sheet metal processing machinery

- Hydraulic presses

- Sliding guides

- Elevating platforms and equipment

- Mechanical conveyors

- Marble and ceramic processing machinery

- Transport trolleys

- Pallet and container racks

- Movable walls

- Sliding gates

- Sliding doors and windows

- Equipment for robotics, electronics and general automation

- Car stands

- Airport loading and unloading equipment

- Sheet metal processing machinery

- Hydraulic presses

- Sliding guides

- Elevating platforms and equipment

- Mechanical conveyors

- Marble and ceramic processing machinery

- Transport trolleys

- Pallet and container racks

- Movable walls

- Sliding gates

- Sliding doors and windows

- Equipment for robotics, electronics and general automation

- Car stands

- Airport loading and unloading equipment

- Sheet metal processing machinery

- Hydraulic presses

- Sliding guides

- Elevating platforms and equipment

- Mechanical conveyors

- Marble and ceramic processing machinery

- Transport trolleys

- Pallet and container racks

- Movable walls

- Sliding gates

- Sliding doors and windows

- Equipment for robotics, electronics and general automation

- Car stands

Ball transfer units

20092 Cinisello Balsamo (MI) - Italy

P.I. / C.F. / Reg. Impr. 08678490965

N. REA: MI-2042305

Cap. soc. € 1.000.000 int. vers.

Please note that any particular and specific technical requirements must always be requested in advance during the quotation phase.